by ARC | Mar 8, 2010 | General

It is estimated that more than 500,000 bone-grafting procedures are performed annually in the United States, with approximately half of these procedures related to spine fusion. These numbers easily double on a global basis and indicate a shortage in the availability...

by ARC | Mar 8, 2009 | General

It is estimated that more than 500,000 bone-grafting procedures are performed annually in the United States, with approximately half of these procedures related to spine fusion. These numbers easily double on a global basis and indicate a shortage in the availability...

by ARC | Mar 8, 2009 | Knee

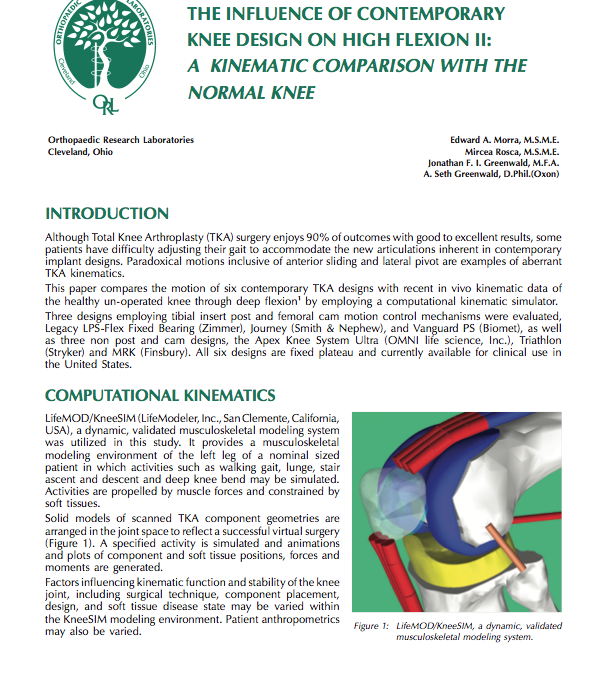

Although Total Knee Arthroplasty (TKA) surgery enjoys 90% of outcomes with good to excellent results, some patients have difficulty adjusting their gait to accommodate the new articulations inherent in contemporary implant designs. Paradoxical motions inclusive of...

by ARC | Mar 8, 2008 | General

It is estimated that more than 500,000 bone-grafting procedures are performed annually in the United States, with approximately half of these procedures related to spine fusion. These numbers easily double on a global basis and indicate a shortage in the availability...

by ARC | Mar 8, 2008 | Knee

Although Total Knee Arthroplasty (TKA) surgery enjoys 90% of outcomes with good to excellent results, some patients have difficulty adjusting their gait to accommodate the new articulations inherent in contemporary implant designs. Paradoxical motions inclusive of...