by ARC | Mar 8, 2012 | Knee

Clinicians, manufacturers and regulatory agencies share a common goal of having safe and effective total knee arthroplasty (TKA) products available in the global marketplace. Preclinical computational modeling of new, innovative knee designs allows dynamic...

by ARC | Mar 7, 2006 | General

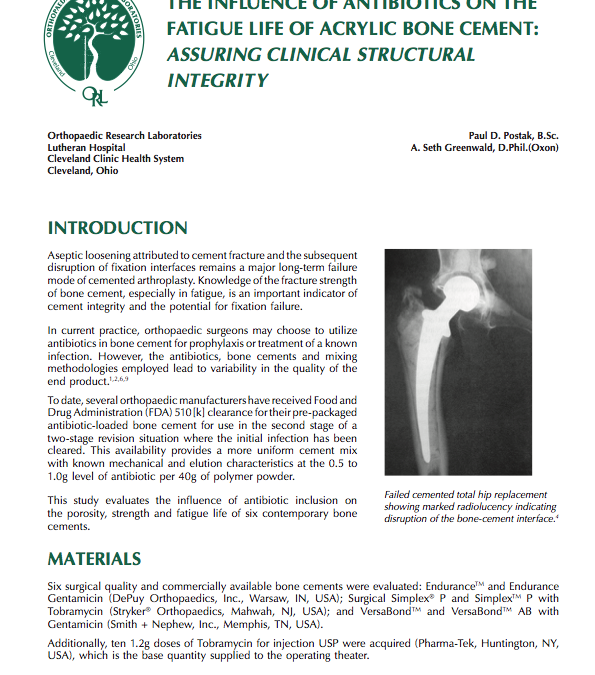

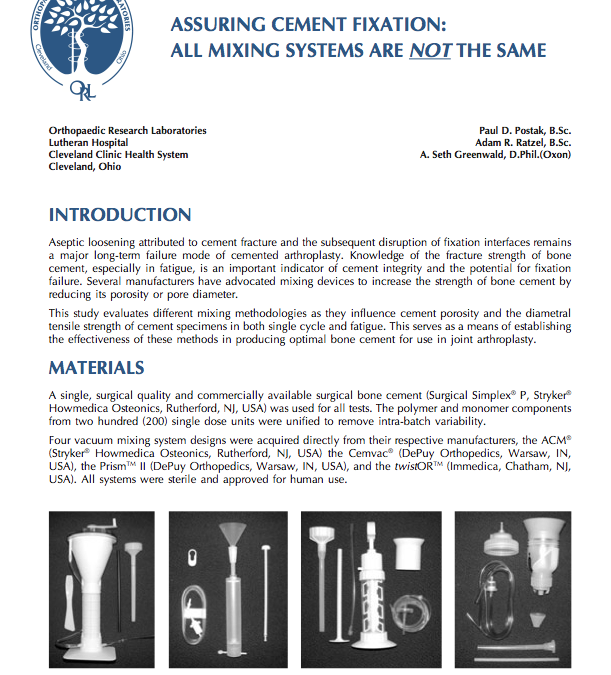

Aseptic loosening attributed to cement fracture and the subsequent disruption of fixation interfaces remains a major long-term failure mode of cemented arthroplasty. Knowledge of the fracture strength of bone cement, especially in fatigue, is an important indicator of...

by ARC | Mar 7, 2004 | General

Aseptic loosening attributed to cement fracture and the subsequent disruption of fixation interfaces remains a major long-term failure mode of cemented arthroplasty. Knowledge of the fracture strength of bone cement, especially in fatigue, is an important indicator of...

by ARC | Mar 7, 2003 | General

The enduring success of the low-friction arthroplasty first advanced by Sir John Charnley as a solution for severe hip arthritic problems may be appreciated from the fact that in 2001 more than 600,000 hip and knee arthroplasties were performed in the United States....

by ARC | Mar 7, 2003 | General

Aseptic loosening attributed to cement fracture and the subsequent disruption of fixation interfaces remains a major long-term failure mode of cemented arthroplasty. Knowledge of the fracture strength of bone cement, especially in fatigue, is an important indicator of...