by ARC | Mar 7, 2005 | General

The enduring success of the low-friction arthroplasty first advanced by Sir John Charnley as a solution for severe hip arthritic problems may be appreciated from the fact that in 2003 more than 800,000 hip and knee arthroplasties were performed in the United States....

by ARC | Mar 7, 2005 | General

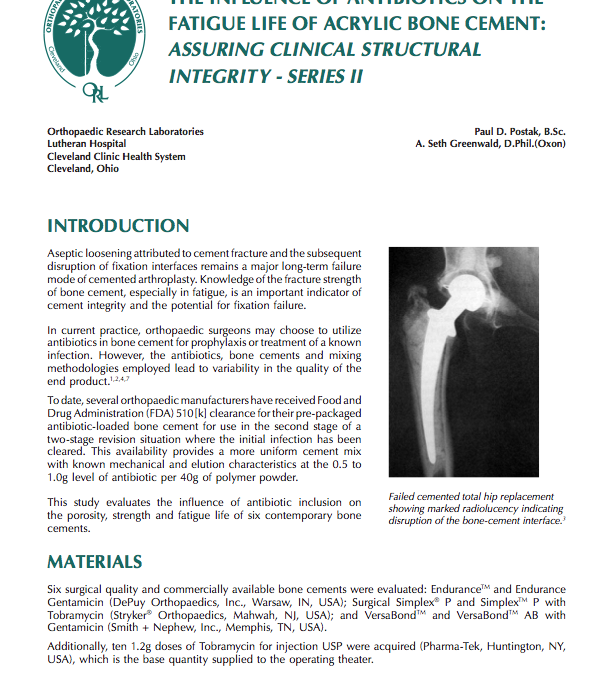

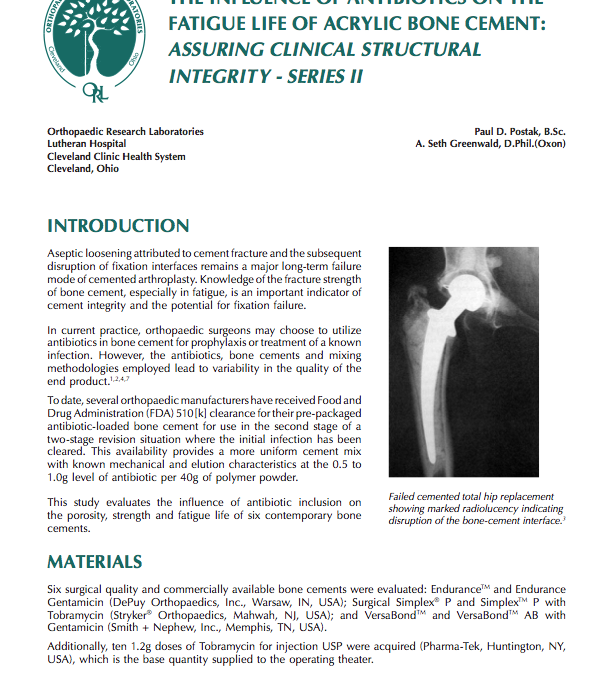

Aseptic loosening attributed to cement fracture and the subsequent disruption of fixation interfaces remains a major long-term failure mode of cemented arthroplasty. Knowledge of the fracture strength of bone cement, especially in fatigue, is an important indicator of...

by ARC | Mar 7, 2003 | General

The enduring success of the low-friction arthroplasty first advanced by Sir John Charnley as a solution for severe hip arthritic problems may be appreciated from the fact that in 2001 more than 600,000 hip and knee arthroplasties were performed in the United States....

by ARC | Mar 7, 2003 | Knee

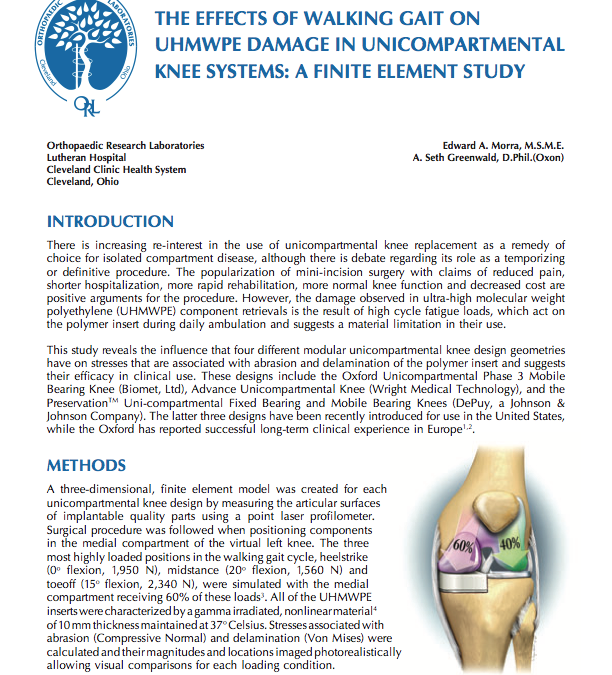

There is increasing re-interest in the use of unicompartmental knee replacement as a remedy of choice for isolated compartment disease, although there is debate regarding its role as a temporizing or definitive procedure. The popularization of mini-incision surgery...

by ARC | Mar 7, 2003 | Hip

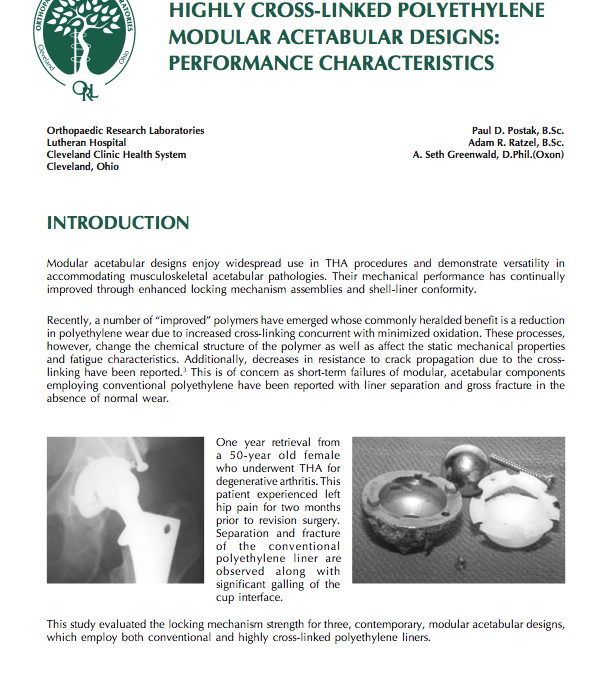

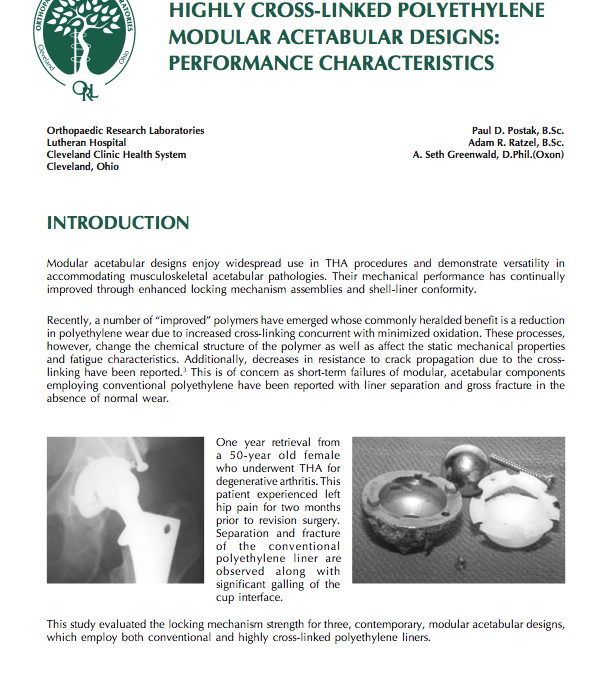

Modular acetabular designs enjoy widespread use in THA procedures and demonstrate versatility in accommodating musculoskeletal acetabular pathologies. Their mechanical performance has continually improved through enhanced locking mechanism assemblies and shell-liner...